JOLLY WORK

Manual stretch wrapping machinesTHE LATEST INCREDIBLY INNOVATIVE IDEA, TWO SYSTEMS IN ONLY ONE: WRAPPER & LIFTER TOGETHER

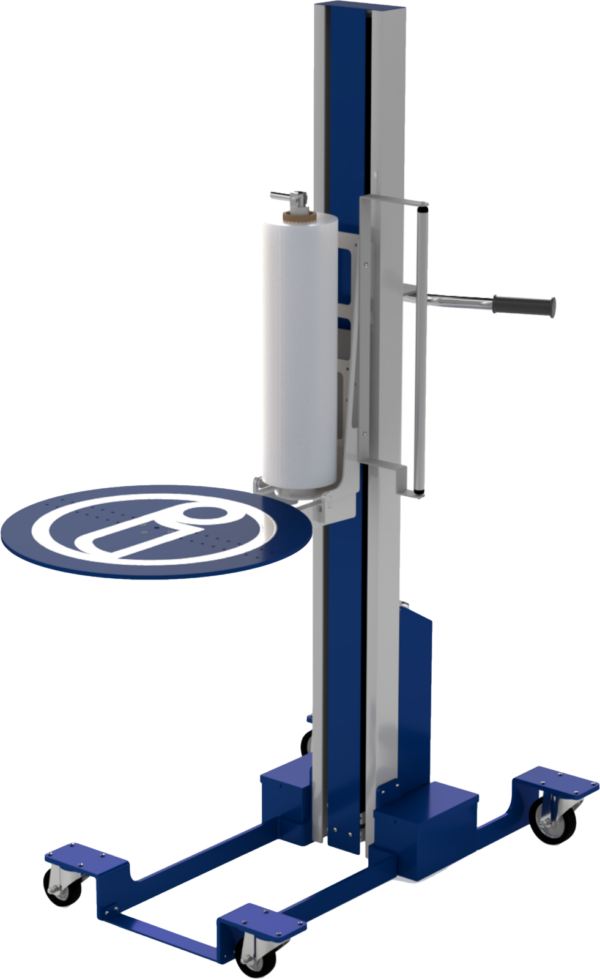

JOLLY WORK LIFTER & STRETCH WRAPPER

Thanks to the “TRANSFORMER” ® device, the lifter and assistant for the stacking of the pallet, Jolly Work, can be immediately converted into a stretch-film wrapper, without parts to be mounted or removed.

JOLLY WORK TO SAVE TIME, MONEY, EFFORTS AND SAFEGUARD THE HEALTH!

Fortunately Jolly Work has arrived…

In terms of health and safety at work, the manual lifting of heavy items and the manual stretch-film wrapping involve serious health risks. Jolly Work increases the productivity and the profitability of the labour, improving the result: it helps and it allows the stretch-film wrapping of higher loads and, in the lifter version, it gives a great help in the preparation of the load.

TECHNICAL SPECIFICATIONS

MORE INFORMATION

THE LATEST INCREDIBLE INNOVATIVE IDEA BY ITALDIBIPACK, THREE SYSTEMS IN ONE

Jolly Work, wrapper and lifter, the 3 in 1 system that solves every packaging need and protects the health of operators. It starts as a simple pallet wrapper with stretch and pre-stretched film (Jolly Wrap), but the addition of the second roll accessory allows the composition of the pallet in half the time (Jolly Twin), while with the addition of the accessory plate (Magic Plate), it also becomes a box lifter and wrapper (Jolly Work), incredibly helpful for the preparation of the load. The device, equipped with various options, can be transformed, without any assembly and disassembly operation, into a pallet wrapper or box wrapper and lifter.

JOLLY WORK TO SAVE TIME, MONEY, EFFORTS AND SAFEGUARD THE HEALTH!

It saves operator effort, preventing back damage, commonly spread among logistics operators, increases productivity and profitability of the work, improves the result, facilitates and allows to wrap higher loads.

DATA SHEET

TECHNICAL CHARACTERISTICS IN LIFTING MODE

- Dimension of the lifting plate: 500 x 450 mm

- Lifting plate in alluminium

- Maximum lifting height: 2000 mm

- Maximum lifting weight: up to 70 kg, with decreasing steps

TECHNICAL CHARACTERISTICS IN STRETCH-WRAPPER MODE

- Standard and/or pre-stretched film with 9-10-12-15 µm thickness

- External film roll diameter: 120 mm

- Stretch-film roll height: 440-450 mm / 500 mm (on request)

- Max core-holder height: 460 mm / 520 mm (500 mm film)

- Internal core Ø: 55 mm

- Maximum pallet height: 2000 mm / 2500 mm on request

- Adjustable film carriage speed

- Regulation of the stretch-film tension through mechanic brake

- Quick release system with the set brake level

PHOTOS AND VIDEO

JOLLY WORK PACKS YOUR PRODUCTS

CONTACTS and SUPPORT

For any technical assistance needs or information about our products, our customer support is at your disposal. We offer a qualified and prompt after-sales service to ensure continuous support. Contact us to find out how we can help you optimize your packaging and wrapping processes with customized solutions.

HEADQUARTER

ITALDIBIPACK S.p.A.

Via Europa, 35

20005 Pogliano Milanese (MI), Italia